Blog | Reading Time 2 minutes

How inoculants can help increase slurry fertilizing value

Manure and slurry are valuable fertilizing elements, providing organic matter for the soil and crops. However, management and handling — from the farm to the field — can lead to logistical and agronomic difficulties. With an estimated 27 m3 of slurry produced per dairy cow and per year, increased efficiency in the nitrogen cycle can help farmers improve returns. Inoculation of manure and/or slurry with selected beneficial bacteria and enzymes is becoming a well-documented way to reduce workload for farmers and improve return on investment through nitrogen retention.

Slurry inoculant: How does it work?

The idea behind slurry inoculants is quite similar to the concept of silage inoculants. Inoculating the raw material (slurry or forage) with specifically chosen bacteria from the start (the inoculant) helps orientate the microbial ecosystem and, thus, fermentation profiles over time.

The idea behind slurry inoculants is quite similar to the concept of silage inoculants. Inoculating the raw material (slurry or forage) with specifically chosen bacteria from the start (the inoculant) helps orientate the microbial ecosystem and, thus, fermentation profiles over time.

At Lallemand Animal Nutrition, we have developed MANURE PRO. It is a highly concentrated combination of live lactic acid bacteria and Bacillus strains with lignocellulolytic enzymes that help improve fiber fermentation during slurry storage. This provides a nutrient source to the microbes in the inoculant, which provides a competitive edge. These positive fermentations help the bacteria retain nitrogen.

Positive impact on nitrogen retention

The application of MANURE PRO on slurry can have a positive impact on nitrogen retention by up to 20%. Depending on the slurry’s initial composition, MANURE PRO can help reduce a farm’s dependency on N fertilizer.

On-farm benefits

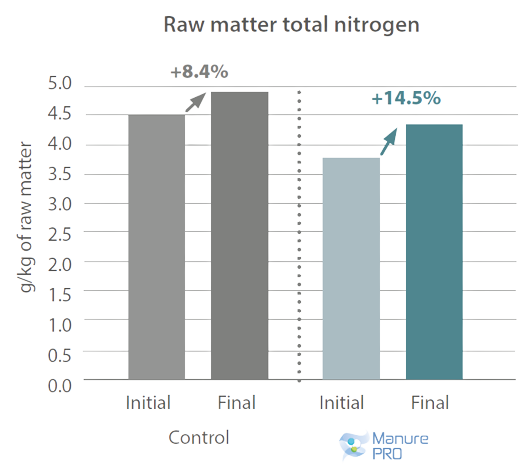

A trial was carried out in a dairy farm in the Netherlands on 110 dairy cows on slatted floors, each producing approximately 77L of slurry per day. This trial showed the pits inoculated with MANURE PRO show better nitrogen retention in the slurry vs. control pits (Figure 1).

Figure 1: Raw matter total nitrogen evolution in control and MANURE PRO slurry pits (Lallemand Animal Nutrition internal data. 2021. Commercial farm, Netherlands).

When looking at the fertilizing value of the slurry, and taking into account the cost of the inoculant, the gain is significant for the farmer: + 1,433€/year for 100 cows, when considering N costs of 3 €/kg. Moreover, the consistency and handleability of slurry are improved (thinner crust), which will reduce fuel and labor costs associated with slurry management.

These trial results indicate that using slurry inoculant can contribute to achieving ambitious EU goals for reducing NH3. In addition, making the best use of the nutrients in slurry can cut the amount of purchased fertilizer needed, providing a crucial opportunity to improve the farm’s bottom line.

Published Apr 11, 2023 | Updated May 29, 2023

Related articles

Need specific information?

Talk to an expert